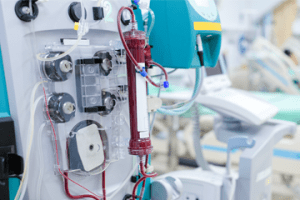

Dialysis machines have been used for decades to help improve the lives of people with kidney malfunctions. Developed in the 1930s, these machines have evolved to ensure the delivery of lifesaving solutions to patients who suffer from kidney complications. The main function of the machines is to monitor the dialysate, which is a fluid used to remove unwanted waste products from blood through a series of membranes embedded in the dialysis machine, simulating kidney function.

Dialysis machines are reused among patients, which categorizes them as reusable devices. Although the tubing and accessories are single use and discarded, the internal tubing within the machine and the exterior of the machine are reused. Reprocessing validations for dialysis machines were not initially required by regulatory authorities, but concern regarding healthcare-acquired infections (HAIs) led to a change in requirements. Regulatory authorities now require that instructions for use (IFUs) go through a validation process. A cleaning and disinfection validation is required. For the internal tubing a disinfection validation is normally also required, since blood does enter the interior loop and can potentially enter the exterior portions. Basically, each portion of the device has its own set of testing requirements, and, therefore, a precise set of outlines for these tests is necessary.

Testing for Internal Tubing

For the internal tubing, ANSI/AAMI 60601 and ANSI/AAMI RD47:2020 contain the guiding testing requirements for disinfection. Waterborne organisms are the target for the disinfection, where a specific log reduction is required for the disinfection process to be considered effective. Disinfection is performed to ensure any bacteria introduced as part of supply water or normal use of the system are cleared and do not result in biofilm or increased colony count or endotoxin, which would cause patient harm. Waterborne organisms are mostly gram-negative organisms and can form biofilm over time and contribute to endotoxin contamination. For this reason, a biofilm test is required, in which a waterborne organism like Pseudomonas aeruginosa is introduced into the circulatory system and allowed to build to challenge the disinfection process. Both chemical and heat disinfection validations are tested for efficacy using designated microorganisms for the process. Typically Pseudomonas species are used for chemical disinfection and Bacillus or Mycobacterium species are used for heat disinfection.

Testing for External Components (e.g., Console, Touchscreen, and Touchpoints)

For testing of external components, low-level disinfection is recommended by ANSI/AAMI 60601 and ANSI/AAMI RD47:2020. Due to a lack of guidance in dialysis-machine standards, acceptance criteria for disinfections for a reusable medical device are used to measure the efficacy of external testing. For low-level disinfection, it is recommended to demonstrate a minimum of 6 log reductions of Pseudomonas aeruginosa, Staphylococcus aureus, Escherichia coli, and Klebsiella pneumonia for the test sites.

Nelson Labs has years of experience performing biofilm testing and can help medical-device manufacturers design and develop a protocol for various types of medical devices that require this testing. Although dialysis machines are very new in the reusable device platform, we are seeing an uptick of related validations that are required by regulatory agencies.