What Packaging Integrity & Strength Testing Does Nelson Labs Perform?

Nelson Labs offers multiple strength and integrity tests for packages depending on packaging type, configuration, and end points. Strength tests include seal peel and burst testing. Integrity tests include bubble emission and dye migration, however additional packaging testing for integrity are also available. Our packaging testing is done in compliance with criteria from:

- ISO 11607

- ASTM F88

- ASTM F1140

- ASTM F2906

- ASTM F1929

Please see our Packaging Validation matrix for more information.

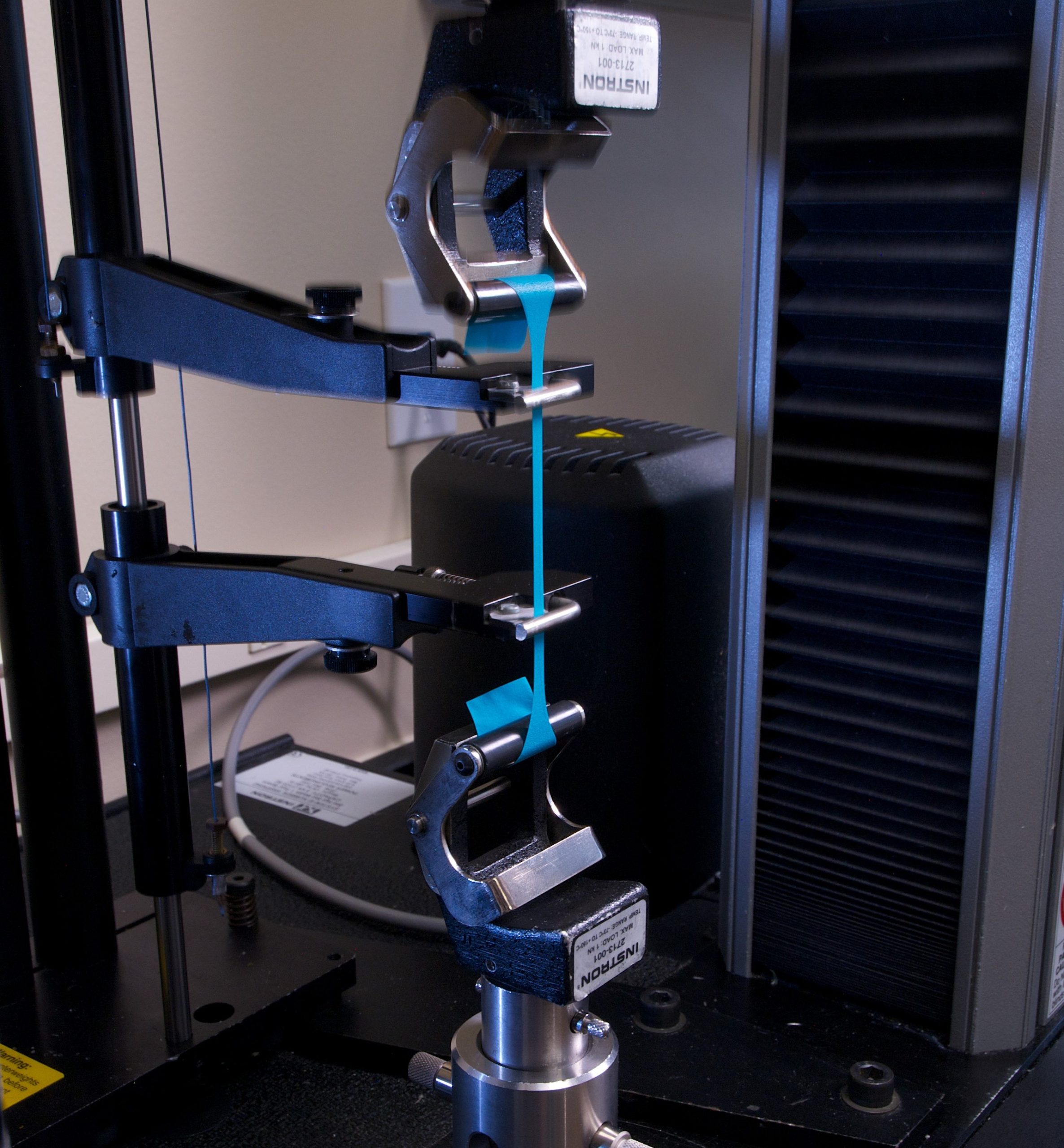

Seal Peel Test

The Seal Peel test determines the strength required to peel apart the seals for porous and nonporous packaging. This test meets the requirements for regulatory agencies to demonstrate the strength of a package seal. This test is performed in accordance with ASTM F88 “Standard Method for Seal Strength of Flexible Barrier Materials.”

Burst Test

The Burst test determines package strength by pressurizing a package until it bursts. This test meets the requirements of regulatory agencies to demonstrate the strength of a package seal. This test complies with ASTM F1140 “Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages.”

Bubble Emission Test

The Bubble Emission test determines package integrity for porous and nonporous materials. It meets the requirements of regulatory agencies to demonstrate package integrity. This test complies with ASTM F2096 “Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test).”

Dye Migration Test

The Dye Migration test determines the integrity of the package seal and enables manufacturers to see if there are channels that leak in the pouch seal. This test is designed to be conducted on porous packaging with a clear side. For double and triple packaging configuration, each article should be tested individually. Nelson Labs performs this test in compliance with ASTM F1929 “Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration.”